Pro-HT Steel

|

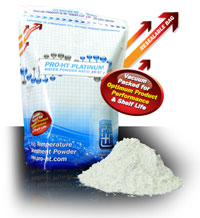

For mixing and burnout instructions see Technical Information. For applications such as stainless steel jewellery, watch parts, body piercings, model parts and rapid prototyping. Maximum recommended alloy temperature for use with Pro-HT Steel is 1700°C / 3090°F. Due to the ever increasing price of precious metal stainless steel jewellery is becoming more popular and global production is rapidly increasing. Pro-HT Steel is designed to produce castings with exceptional dimensional accuracy and detail reproduction with high level of surface finish. Pro-HT Steel is invested using the traditional rubber base and steel flask system and can be burnt out using the Pro-HT burnout cycle 90 minutes after investing. Pro-HT Steel may be used to burn out waxes and SLA models, however please note that the surface finish achieved when casting SLA models may be inferior to castings made from standard waxes. Pro-HT Steel is vacuum packed in 10KG Aluminium Foil Laminate bags with an easy zip lock to reseal the bag once opened. This type of packaging has never been available to the investment casting industry before and is exceptionally important as phosphate bonded products are extremely sensitive to atmospheric moisture and exposure will instantly degrade the products performance. For further information please email us at info@pro-ht.com. |

|